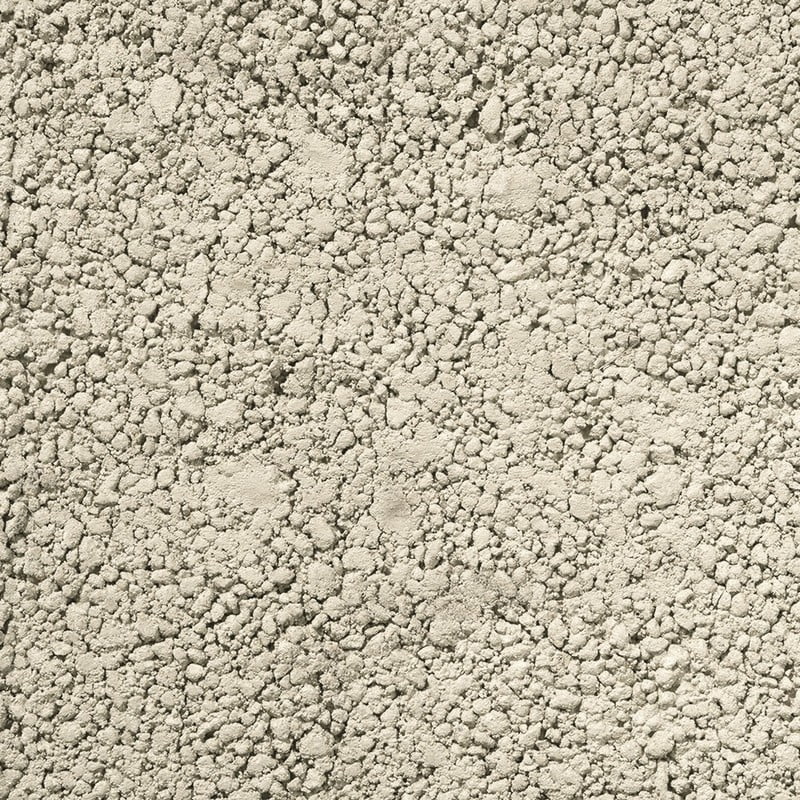

Description

Please note: Goldpath is supplied to order and is non-returnable. Lead time typically 5-7 working days. Due to the nature of this material and quarry conditions, we do not supply Goldpath in winter months.

Goldpath Self Binding Gravel provides a sympathetic, attractive rich golden surface, which is easy to lay and maintain. Its natural setting properties bind the gravel together when rolled, to provide a self compacted firm finished surface, which remains firmer under foot than conventional loose aggregate. This also makes it ideal for projects where access and mobility for the user is a priority. Goldpath’s unique properties are suited to a wide spectrum of applications from domestic driveways and footpaths to commercial sector projects that require a cost effective durable surface and which is easy to lay and maintain. Goldpath is supplied in bulk bags (approx. 900kg or 0.6 cubic metre). Goldpath self-binding gravel is sometimes used as an alternative to hoggin, though it has less clay content.

Please click here for laying instructions and frequently asked questions.

Laying method:

- Foundation: A suitable foundation, incorporating all falls and profiles and providing a free draining porous surface is essential to ensure that no water is held directly under the surface of the Goldpath. This foundation should then be compacted with a roller not weighing less than 1 tonne to provide a flat level surface.

- Spread: A flat boarded rake is then used to level and spread the Goldpath to its finished surface level of 50mm for footpaths and 100mm for vehicular paths.

- Dry rolling: The surface is then rolled DRY with the roller set to its maximum vibration and the surface rolled to its fullest compaction. If patchy areas appear, fines (dust) can be sieved from the surplus heap to bind these segregated areas and re-rolled to provide a smooth uniform surface.

- Wet rolling: Once a consistent flat uniform surface has been achieved, the water rolling of the surface can be carried out. This process floats the finer grades of the Goldpath to the surface, a fundamental process in ensuring the product binds together and sets sufficiently. Water needs to be sprinkled directly onto the surface of the rollers continually throughout this process with the vibratory action on the roller switched OFF. It is imperative that the water is only sprayed or sprinkled directly onto the roller NEVER directly onto the surface of the Goldpath as this would wash out the fines and minimise the product’s natural self binding properties. The wet rolling is continued until a smooth, compacted even surface is achieved. This should then be allowed to dry and set for a minimum period of 48 hours. Avoid laying in extremely cold or frosty conditions.

Reviews

Reviews (0)

There are no reviews yet.